Thank you for contacting us.

We will respond as soon as possible.

THE IMPORTANCE OF ACOUSTICS IN BUILDING COMFORT: REGUPOL COMFORT 5 AND EDILTECO SOLUTIONS FOR INNOVATIVE CONSTRUCTION

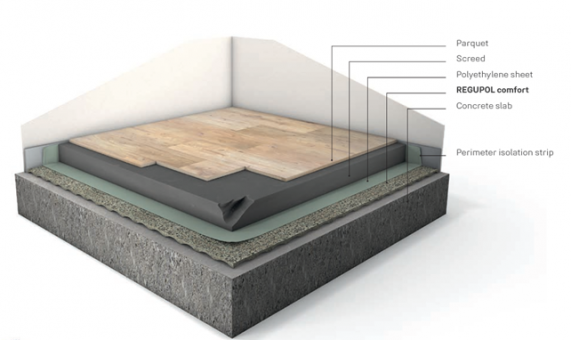

In today's construction landscape, acoustic comfort is a key design variable, both in residential and commercial environments. The UNI 11944 standard has introduced precise guidelines for the design of flooring systems, emphasizing the role of acoustic insulation and the need to adopt materials that ensure high performance over time. In this context, Regupol Comfort 5, combined with Edilteco technologies, represents an advanced technical solution capable of meeting regulatory requirements, eliminating critical issues such as hygrometric shrinkage, and ensuring dimensional stability and structural durability.

Regulatory Integration and Technological Innovation

The Italian standard UNI 11944 specifically focuses on the required characteristics for floating screeds and subfloors, which are crucial elements for impact and airborne noise insulation. Specifically, paragraph 5.2 highlights that the subfloor must have dimensional stability, mechanical resistance, and be free from deferred hygrometric shrinkage. Edilteco products, designed to meet strict performance standards, stand out for their ability to maintain an unchanged level over time—an essential parameter for ensuring stable and long-lasting acoustic and structural performance.

Regupol Comfort 5 is a material composed of elastomers bonded with polyurethane (PUR). It stands out for a series of characteristics that make it an optimal solution for acoustic comfort in construction:

-

Impact noise reduction (ΔLw ≥ 20 dB): A proven performance that significantly improves the acoustic well-being of environments.

-

Reduced thickness (5 mm): A particularly useful feature in situations where the available floor system height is limited.

-

High compressibility (c-value): Greater than that of traditional mineral wool, allowing it to support traffic loads up to 500 kg/m² while maintaining its acoustic performance.

-

EPD Certification (Environmental Product Declaration): The material meets sustainability requirements, with an Embodied Carbon of 0.91 kg CO2e/m² (for production stages A1-A3), demonstrating a low environmental impact.

The integration of Regupol Comfort 5 with Edilteco subfloors, free from hygrometric shrinkage, provides a comprehensive technical solution that not only improves acoustic comfort but also ensures long-term dimensional stability and mechanical resistance.

Applications and Benefits in the Construction Sector

Solutions that combine Regupol Comfort 5 and Edilteco subfloors are applied in a wide range of construction projects, from new builds to renovations, with particular effectiveness in residential and commercial settings. The combination of materials that strictly comply with the UNI 11944 standard allows for meeting the most demanding design requirements, addressing issues related to acoustic comfort, structural stability, and sustainability.

Conclusions

The use of advanced materials such as Regupol Comfort 5 and technologically evolved Edilteco subfloors represents a significant advancement in construction design. These solutions enable the creation of buildings that comply with current regulations, reduce environmental impact, and optimize residential and workplace comfort. The adoption of such technologies offers designers and builders a concrete opportunity to define new standards of quality, sustainability, and innovation in the construction sector.

SHARE